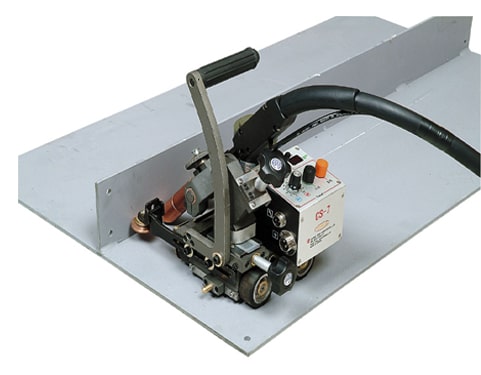

- 다층 용접 전용캐리지입니다. (수동토치,자동토치 사용 가능)

- 적층 용접각도에 따라 토치조정을 2개의 슬라이드로 0~75°까지 쉽게 가능합니다.

- Gear Backlash를 최소화하여 정속주행하므로 용접품질을 극대화했으며 장비 수명이 길어 집니다.

- 경사각도는 75도까지 용접가능하며, 터치 센서로 용접이 끝나면 자동정지 합니다. .

- 크리에트 기능을 부여하므로 용접시작 종료 부분에 용접품질이 우수합니다.

- Magnet handle을 채용하므로 쉽게 탈착이 가능합니다.

- 크기와 무게를 최소화 하였으며 사용 및 이동이 편리합니다.

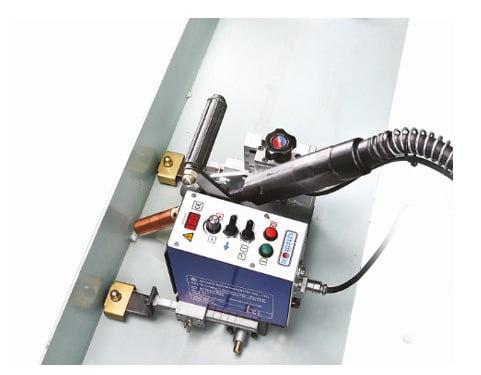

- 수평필렛 자동 용접 범용캐리지이다.

- T.G 제어방식으로 정속주행과 정확한 속도를 표시한다.

- 자석레바 방식으로 탈부착이 편리하고 위치 셋팅이 쉽다.

- 양방향 용접이 가능한 기능이 내장 되어 있다.

- 간단한 조작으로 작업자가 크레이트 시간을 조절하도록 되어있다.

- 캐리지를 경량화하여 작업자의 피로감을 감소시킨다.

- T.G 제어방식으로 정속주행과 정확한 속도를 표시한다.

- 자석레바 방식으로 탈부착이 편리하고 위치 셋팅이 쉽다.

- 양방향 용접이 가능한 기능이 내장 되어 있다.

- 간단한 조작으로 작업자가 크레이트 시간을 조절하도록 되어있다.

- 필렛 용접용으로 단속용접과 연속용접이 원하는 mode세팅으로 가능합니다.

- Gear Backlash를 최소화하여 정속주행하므로 용접품질을 극대화했으며 장비 수명이 길어 집니다.

- 경사각도는 75도까지 용접 가능하며 양면에 부착된 터치 센서로 용접이 끝나면 자동정지 합니다.

- 캐리지는 U-보강재 상면을 주행하지만 토치는 바닥면을 주행하므로 RIB와의 편차를 보상하여 줍니다.

- 크리에트 기능을 부여하므로 용접시작 종료 부분에 용접품질이 우수합니다.

- Magnet handle을 채용하므로 쉽게 탈착이 가능합니다.

- 크기와 무게를 최소화 하였으며 사용 및 이동이 편리합니다.

- 필렛 용접용으로 단속용접과 연속용접이 원하는 mode세팅으로 가능합니다.

- Gear Backlash를 최소화하여 정속주행 하므로 용접품질을 극대화했으며 장비 수명이 길어집니다.

- 경사각도는 75도까지 용접가능하며 양면에 부착된 터치 센서로 용접이 끝나면 자동정지 합니다.

- 크리에트 기능을 부여하므로 용접시작 종료 부분에 용접품질이 우수합니다.

- Magnet handle을 채용하므로 쉽게 탈착이 가능합니다

- 단속용접과 연속용접, 속도 단위 세팅은 사용자 매뉴얼 참고.

- 수동토치와 자동토치 모두 사용가능합니다.