Skip to content

- The non-welding section of the T-Bar was minimized.

- The position of the rail can be easily readjusted by the on-off mag switches.

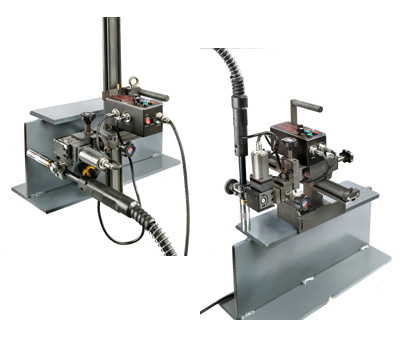

- 1 machine can be used for both of left and right welding.

- It is specialized in Corner and T-Bar welding.

- The welder drives on the wheels with the guide rollers moving on the flexible rail, and it is controlled by the panel controller and the remote controller.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- Controlling the weaving width, the desired leg length can be acquired in 1 time travelling.

- The position of the rail can be easily readjusted by the on-off magswitches.

- The travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

- It is a butt multi-layers welder for the outer side of pipe and vessel, and the diameter should be more than 2000mm.

- The welder drives on the wheels with the guide rollers moving on the flexible rail, and it is controlled by the panel controller and the remote controller.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- Min. above 3 meter bending radius of the rail and easy to in-line by Magnet On-Off switch.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- Controlling the weaving width, the desired leg length can be acquired in 1 time travelling.

- Using magnet release handle, it can be easily mounted and dismounted.

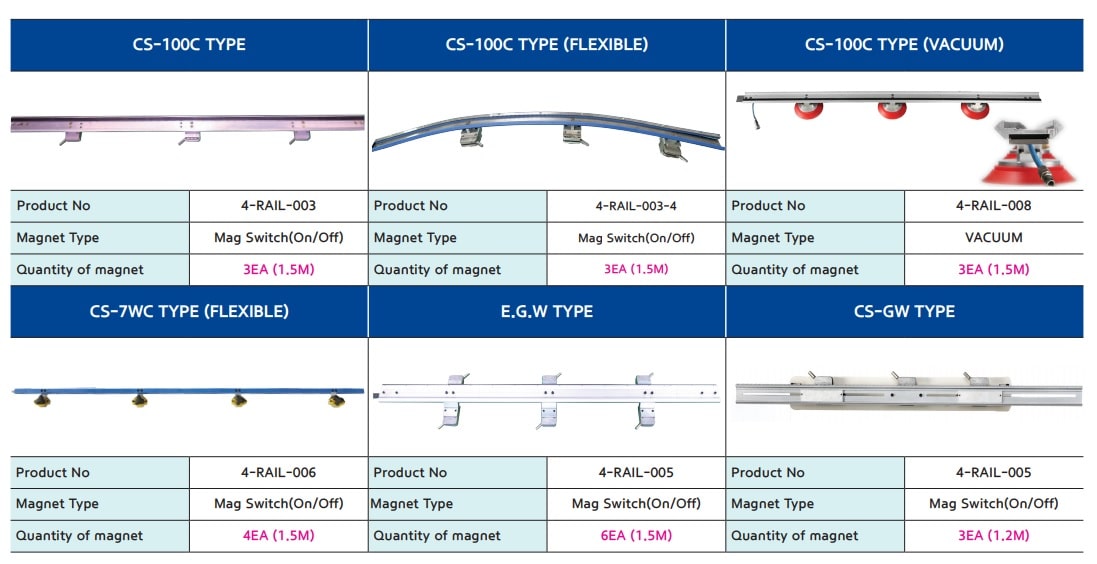

- CS-100C TYPE, CS-100C TYPE (FLEXIBLE), CS-100C TYPE (VACUUM)

- CS-7WC TYPE (FLEXIBLE)

- CS-EGW RAIL

- CS-GW TYPE

- CS-PW TYPE

- CS-100CP TYPE

Translate »