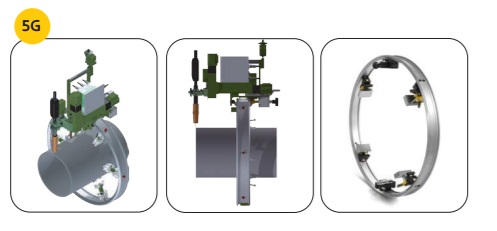

CS-100CP LCD Automatic Multi-Layers Welder for Pipe

Home » Products » Rail Travelling Fillet » Rail Pipe » CS-100CP LCD Automatic Multi-Layers Welder for Pipe

Detail Info

• It is possible to control the motor by memorizing the start position and angle of the torch for each multi-layer PASS.

• The welder weldes pipes.

• It searches for welding points along the rail and is suitable for horizontal welding position.

• By controlling the location and angle of the torch with a motor, the operator’s fatigue can be reduced

through the convenience of operation and the reduced setting time of the equipment.

• The fixing device for the pipe rail is manufactured as a unit, so it is possible to apply transformation

up to ±50Ø of the pipe size.

| DIVISION | CS-100CP | |||

|---|---|---|---|---|

| General | AC Input Power | AC100V~240V 50/60Hz | ||

| DC Input Power(Option) | AC 48V | DC18-72V(Option) | ||

| Dimensions | 206(W) X 452(L) X 330(H) | |||

| Weight | 8.5Kg | |||

|

Body(X) |

Driving Method | Rack-Pinion Driven | ||

| Traveling Speed | 0~88 cm/min | |||

| Traveling Motor | DC 24V, 12W, 5000RPM BLDC | |||

| R | Motor | DC 24V, 12W, 5000RPM BLDC | ||

| Worm Auto Slide | 0~360 ˚ | |||

| Weaver | Motor | DC 24V, 12W, 5000RPM BLDC | ||

| Weaving Width | ±4˚ ±5% | |||

| Weaving Speed | 0~5 rpm/min | |||

| Left/Right Stop | 0.0~9.9(sec) | |||

| Center Shift | 0~360 ˚ | |||

| Operating Distance of RC | 10m | |||

| Z | Motor | DC 24V, 12W, 5000RPM BLDC | ||

| In Out Auto Slide | ±25mm | |||

| Rail | Fixing | Magnet ON/OFF Type | ||

| Material / Size | AL /1.2M /9.4Kg | |||

| Welding Position | Fillet | Groove | PIPE |

| 5G |

Rail Pipe

Rail Pipe