Products

Battery Carriage

- Applicable to all model types supplied by Cheongsong Industrial Machinery

- Operates without a power cable and is powered by a proven battery (DC power) for safety.

- The carriage body is equipped with a socket for removing and installing batteries

Fillet Carriage

- Applicable to various members/materials in fillet weld positions (1F,2F,3F,4F)

- Single-sided, double-sided, double-sided, wall, tantem, multi-layer, U-RIB, I-BAR, ANGLE BAR, etc. to match the welding area of the member/substrate

Available for each model type

- Customizable for continuous welding function, detachable handle, torch clamp position/orientation, guide roller type, product size/weight, etc.

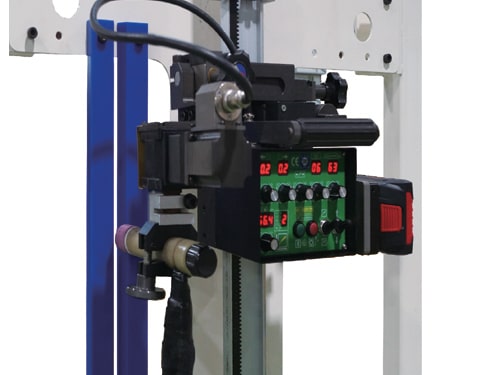

Oscillator

- Ideal for curved weave welds (clockwork), down view/fillet circumference welds

- Column, Turning Rotator required separately

- Pantone-type controlbox above the weaving function (straight line, curve selection)

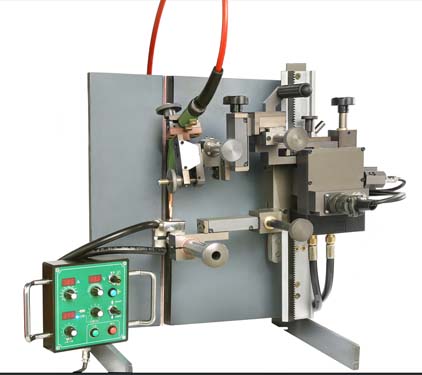

Railless Weaving

- Applicable to various members/materials in fillet weld posture (2F, 3F, 4F)

- Rail-less driving, weaving function, wireless remote control

Rail Travelling Fillet

- Applicable to members/materials with fillet welds (2F,3F,4F) and butt welds (1G,2G,3G)

- Various rail attachment methods (magnetic, on/off magswitch, vacuum pump, flexible, etc.)

- Rail Ride, Weaving, Wireless Remote Control

E.G.W

- Suitable for welding thick plates using Electro Gas Welding (EGW) welding techniques

- Rail travel, weaving function, wireless remote control, stick-out control

Heating/Back Heating

- ship block heating and back heating processes.

- Skip heating / Continuous heating/ Adjust point-to-point separation / Adjust point-stop time / Adjusting the Driving Speed

ETC.

- Automation Peripherals for Welding

: Mechanized CO2 Torch, Manual CO2Torch