Skip to content

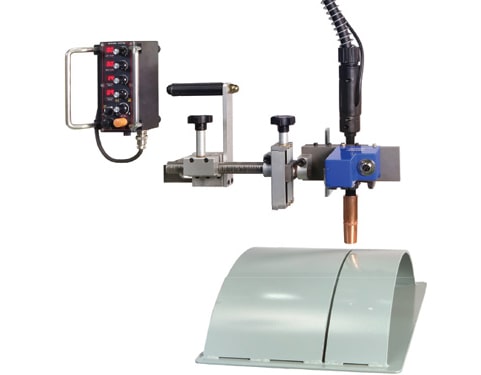

- It is a butt & fillet welder for circumference, and the column & boom, and the rotator are needed additionally.

- It makes linear movement, and the leg length of high quality as much as you want can be acquired.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- It is a butt & fillet welder for circumference, and the column & boom, and the rotator are needed additionally.

- It makes pendulum movement, and the leg length of high quality as much as you want can be acquired.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- It is specialized in fillet multi-pass welding. Adjusting the angle slide of worm gears and the Y slide of forward and backward movement, the position of the torch can be set.

- Using a single machine, both of 2 welding (upper/lower) parts can be welded.

- The multi-pass welding is done when a bigger weld throat is needed.

- It can climb up to 75° of inclination, and the stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- Using magnet release handle, it can be easily mounted and dismounted.

- The travel speed in Cm/Min or Inch/Min programmable in acc with the User Manual.

- Automatic welder for wind tower bracket and boiler tubesheet.

- The display screen shows the exact driving speed.

- The constant speed driving is controlled by a microcomputer to achieve precision driving, so the welding quality (leg length) is constant.

- When welding is stopped, the built-in automatic crating function improves the welding quality.

- It is convenient to set the working position with an easy torch adjustment device.

- After welding started, it welds one turn and stops welding automatically.

- After 1 cycle automatic welding completed, it welds in the opposite direction to prevent cable twisting.

- It is a wall travelling fillet welder with stitch function and 2 torches.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- It is small and light, so it can be conveniently used and easily moved.

- Stitch, Continuous welds and the travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

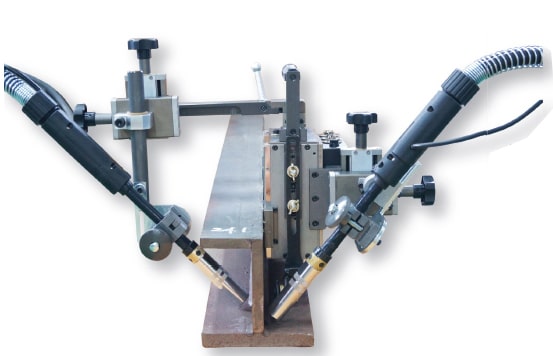

- It is a wall travelling fillet welder for I and H Beam, and the Beam height should be more than 120mm.

- It is a fillet welder with stitch function.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- It is small and light, so it can be conveniently used and easily moved.

- Stitch, Continuous welds and the travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

- It is a wall travelling fillet welder with stitch function for I & H Beam, and the Beam height should be more than 120mm.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- Using magnet release handle, it can be easily mounted and dismounted.

- It is small and light, so it can be conveniently used and easily moved.

- Stitch, Continuous welds and the travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- Using magnet release handle, it can be easily mounted and dismounted.

- It is small and light, so it can be conveniently used and easily moved.

- The dual side welding with 2 torches can save time and cost.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- It can climb up to 50° of inclination, and the stop sensors of its both sides stop the welder automatically when a welding job is completed.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- It is small and light, so it can be conveniently used and easily moved.

- Stitch, Continuous welds and the travel speeds in Cm/Min or Inch/Min programmable in acc with the User Manual.

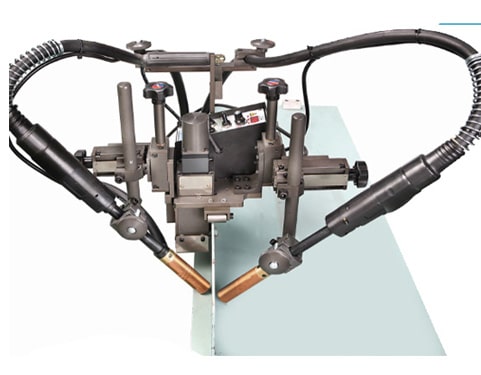

- It is a dual side fillet welder of U-Rib.

- The single or dual side welding is selectable, and the arm height of the welder is adjustable according to the size of U-Rib.

- The additionally equipped tension slide makes the welding tracing constant and the high welding quality.

- While the welder travels on the U-Rib, the guide rollers of the tension slides move on the side plates and it makes the constant arc height in welding.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

Translate »