Skip to content

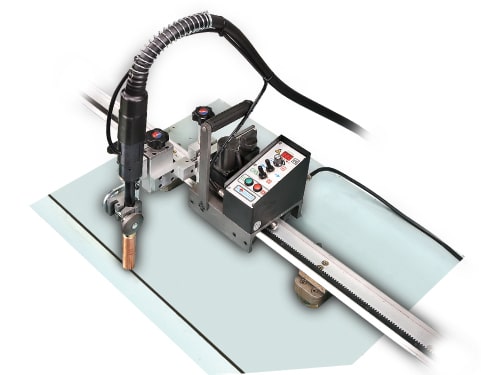

- It is a weaving welder of multi-positions driving on the aluminum rigid rail, and it can be easily controlled by the panel controller and the remote controller.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- Controlling the weaving width, the desired leg length can be acquired in a travel.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The position of the rail can be easily readjusted by the on-off magswitches.

- It is specialized in TIG weaving welding( installed with high frequency dedicated TIG PCB )

- It is a mini ultra-light EGW Welder.

- With Vertical-Up 1pass welding (30T or less), it can make welding bead shapes on the back (using ceramic backing material) and the front (using copper shoe).

- It reads the value of current between the welding gap in & out, and controlling the arc length by the difference compared to the input value it forms automatically a melting pool.

- It uses the BLDC (driving, weaving) motors, so it has good durability and excellent ability to respond to driving speed depending on the thickness of the base material.

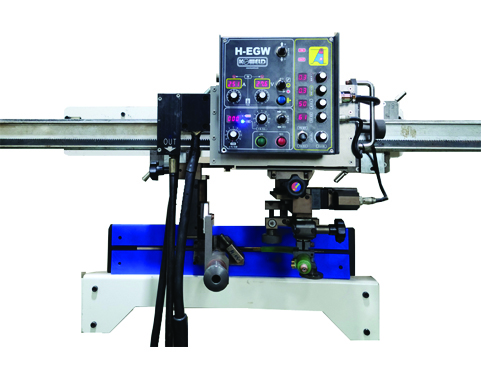

- It is a horizontal, butt weaving welder of EGW (Electric Gas Welding), and FCAW (Flux Cored Arc Welding).

- Driving on the rail, it follows the welding points and makes a high-quality welding bead shape with a weaving device of weaving patterns, and a copper shoe suitable for horizontal welding.

- It reads the value of current between the welding gap in & out, and controlling the arc length by the difference compared to the input value it forms automatically a melting pool.

- It has a feedback control device for changes in driving speed due to load, so it makes excellent ability in constant-speed driving.

- It uses the BLDC (driving, weaving) motors, so it has good durability and excellent ability to respond to driving speed depending on the thickness of the base material.

- It is a vertical-up, butt weaving welder of Electric Gas Welding, and the welding thickness of 25 ~ 50mm is acquired with 1 pass.

- It is applicable for ship blocks or large storage tanks.

- The bead is formed while the machine goes up with the copper shoe, and it is cooled by fresh water circulation.

- The position of the rail can be easily readjusted by the on-off magswitches.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- It is small and light, so it can be conveniently used and easily moved.

- Butt welder by Electric Gas Welding for vertical-up direction with thickness of 10-25mm by one pass where no weaver needs.

- Applicable to ship's blocks and larger storage tanks.

- Stick-out and travelling speeds in automation by means of detecting various currents providing from melt metal height in the bath.

- The bead is performed while the machine goes up with copper shoe and cooling by fresh water circulation.

- The control of the machine is possible both from the control panel and wired control panel.

- Magnet On-Off switch type rail offers in-line adjustment easily.

- Minimized gear backlash offers various constant speed/adjustable controls precisely, thus the highest quality welding and a long life by means of a special motor with a reducer.

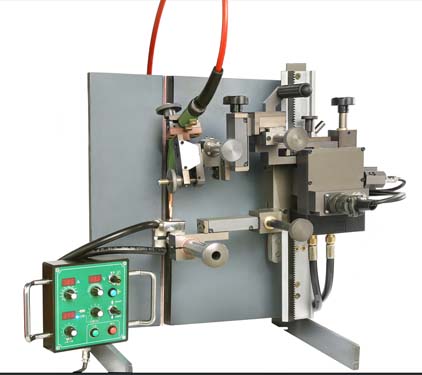

- Storable the starting position and angle value of the torch for each multi-layer PASS.

- [Semi-automatic mode] Torch is automatically moved to the memorized starting position with the angle value of the next work PASS when ongoing PASS welding is completed.

- [Manual mode] The origin return button is pressed, and torch is moved to the memorized starting position with angle value of the next work PASS.

- Up to 15 PASS, working condition values can be set and saved.

- Mechanical downsizing and simplification of equipment enables welding in narrow spaces and short sections.

- By adjusting the position of the magnets on the rail, the rail can be easily installed on site.

- The welder is compact and lightweight, so it can be moved easily and conveniently.

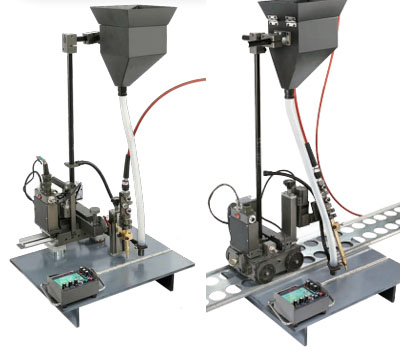

- Productivity can be improved and welding cost can be reduced in flat position SAW welding work.

- A weaving device is installed so that even thick base materials can be welded, and the weaving width can be adjusted according to the thickness.

- There is a left and right stop function to prevent insufficient penetration and undercut during weaving welding.

- It is possible to do precise control digitally such as running speed, weaving width, weaving speed, left stop, right stop and etc.

- Using the lightweight rail with magswitch, the welder can be conveniently moved and easily installed.

- The welder is compact and lightweight, so it can be moved easily and conveniently.

- Productivity can be improved and welding cost can be reduced in flat position SAW welding work.

- A weaving device is installed so that even thick base materials can be welded, and the weaving width can be adjusted according to the thickness.

- There is a left and right stop function to prevent insufficient penetration and undercut during weaving welding.

- It is possible to do precise control digitally such as running speed, weaving width, weaving speed, left stop, right stop and etc.

- Using the lightweight rail with magswitch, the welder can be conveniently moved and easily installed.

- It is a weaving welder of multi-positions driving on the aluminum rigid rail, and it can be easily controlled by the panel controller and the remote controller.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- Controlling the weaving width, the desired leg length can be acquired in 1 time travelling.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The position of the rail can be easily readjusted by the on-off magswitches.

- The travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

- The position of the rail can be easily readjusted by the on-off magswitches.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- The crater filling function provides excellent welding quality at the beginning and end of welding.

- The travel speed in Cm/Min or Inch/Min programmable in acc with the user manual.

Translate »